What is a Thermic Fluid Heater? |

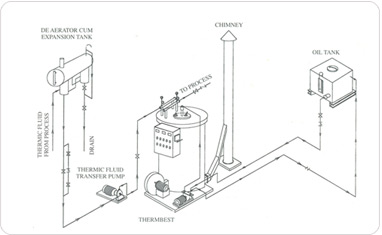

| It is a heat source that can supply heat of temperature from 300 c to Very Temperatures, It heats a fluid (Thermic Fluid) to required temperatures and the fluid then be passed to process points where heating is required . The heat energy can be extracted from this hot Thermic fluid by means of radiation by circulating the fluid around vessels that need to be heated or by other suitable means and finally recycled to the Thermic Fluid Heater. |

| Where can you use a thermic Fluid Heater? |

Where ever indirect heating at temperatures in the range of 30 0 C to Very High Temperatures is required , it could be used. |

| Why Thermic Fluid Heater instead of Steam Boiler? |

| Generally in a Steam Boiler, high temperature steam is obtained only at high pressure. That is, if the temperature of the steam is increased the pressure would also increase. Understandably this high pressure is a safely hazard. But for a Thermic fluid Heater no such high pressure risk exists because the fluid’s temperature could be increased without any increase in the pressure. Future, Steam Boiler requires water for its operation and hence it can be used only at places where proper water source is available. Whereas Thermic Fluid Heaters can be used even if there is no water source. |

Thermbest has the following safeties and controls.

Temperature indicator cum Controllers to indicate temperature and prevent undesired overheating at the inlet and outlet of the system.

Stack temperature controller to cut off the Thermic Fluid Heater when the flue gas temperature exceeds the set level and to act as a counter check for temperature indicator cum controller at oil outlet line.

Photo cell to sense flame failure, give alarm and switch off the burner.

Magnetic level switch in the deareator cum expansion tank to cut off the burner if the thermic fluid level falls below the minimum level.

Synchronising mechanism exists between the hot oil circulation pump and burner, so that the burner will not be switched on until the circulation pump reached the full speed.

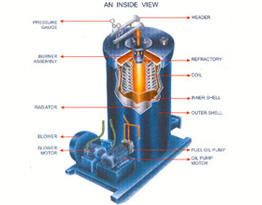

In Thermbest, there are two differently sized helical shaped seamless tube coils, with the gaps between their turns closed. These two coils are placed concentrically inside a cylindrical shell. A fine jet of combustible fuel is sprayed inside the chamber formed by the inner coil and ignited. This results in combustion and the not flue gas thus formed is blown down by air from the top. The flue gas then passes from this chamber to the path between the two coils, then, between the outer coil and the shell enclosing it and finally goes to the exit. The Thermic Fluid is passed through is two coils where it absorbs heat energy from the flue gas. Then it is sent to the process where heating is required. After the heat energy is extracted at the process the Thermic Fluid is recycled to the Thermic Fluid Heater.

FLUID AUTOMATIC

Manual operation is not necessary since Thermbest is a complete automatic system.

USE FRIENDLY CONTROL PANEL

Thermbest has a dust and vermin proof control panel with relays. contractors, programmers, control switches, alarms etc., inside it. Various functions like temperature setting , pressure setting can be easily done with help of switches on the panel. There are separate indicator lamps to indicate the working condition of every component in the system. There are indicator lamps even to show various parametric conditions and status of the safeties.

HIGH EFFICIENCY

Thermbest is designed it give a high thermal, efficiency of 88 + /-2%.

COMPACT

Thermbest is designed to be very compact and thus occupies minimum floor space. It can be kept the process point itself.

HIGH QUALITY COILS

The coils provided in Thermbest are made out of High Temperature Seamless Tubes. This ensures longer life and trouble- free performance of the coils.

HIGH OVERALL QUALITY

The steel plates, seamless tubes and other components that are used to male. Thermbest are handpicked and are of high quality. All other components from nuts, bolts to valves, motors and pumps are of reputed makes in Thermbest, it is ensured that a high level of workmanship is involved in the making of every Thermbest Further, every Thermbest undergoes strict quality control of our products and services. All these make Thermbest a completely reliable, high quality product.

RELIABLE AFTER SALES SERVICE

Enough number of qualified, experienced and dedicated service personnel and our stocking of all spare parts ensured that the breakdown calls are immediately attended and rectified. Our customer-care-cell gets regular feedbacks from customers about the quality of our products and services. We constantly work towards further improvements in these areas.

Horizon Softnet Solutions

Horizon Softnet Solutions