Our Solid fuel Fired Packaged boilers are specially designed for manual operation by fireman. The furnace is fitted with specially designed heat resistant fire bars. Solid fuels are fed manually on the bars.

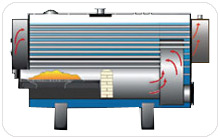

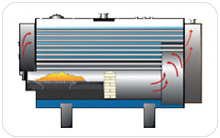

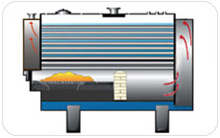

Primary air flows into the furnace through The openings in the fire bar. The fire bars are So designed they are kept cool by the Cooling action of the primary air, Secondary air flows into the furnace Through the openings provided in the front End of the furnace. This air imparts a Circular motion to the flame and the Combustion gases. An induced draught fan Maintains a negative pressure in the Furnace. This unique proportioning of the Two streams of primary air and secondary Air prevent ash fusion and clinker formation . This also ensures complete combustion of the fuel.

Semi / wet-back chamber located in the rear Of the furnace effectively absorbs the flames entering it, ensures complete turn around and mixing of the gases prior to entering the second pass. Access Door is provided on the rear wall f the chamber to facilitate quick removal of fly- ash, thus avoiding chocking in the tubes. The front smoke box also ensures complete turn around the mixing of the gases prior to entering the third and final pass of smoke Semi / wet-back chamber located in the rear Of the furnace effectively absorbs the flames entering it, ensures complete turnaround and mixing of the gases prior to entering the second pass. Access Door is provided on the rear wall f the chamber to facilitate quick removal of fly- ash, thus avoiding chocking in the tubes. The front smoke box also ensures complete turn around the mixing of the gases prior to entering the third and final pass of smoke tubes. As all the useful heat is absorbed, the thermal efficiency is as heat is absorbed, the thermal efficiency is as high as 75 =/-3% based on GCV Of Solid fuel as 3000 - 3500 Kcals/kg.

CONSTRUCTION

Our boilers are manufactured in accordance With the stringent standards laid by the Indian Boiler Regulation codes. The boilers are so Designed to guard against excessive thermal Stresses. The boilers are manufactured using Boiler quality steel plate and tubes .The quality Is ensured in the manufacturing process it self which reduces rejections are reworks All the longitudinal and circumferential seams are X-ray inspected and the boilers are stress relieved wherever necessary before hydro testing.

ELECTRICAL CONTROLS

Fully dust proof control panel houses all the Relays and controls required for the safe operation Of the boiler and its accessories. Overload protection ensures that motors do not get overheated.

STANDARD SCOPE OF SUPPLY

- Boiler with furnace, semi / wet back Chamber, smoke tubes and fusible plug Manufactured, tested and certified with front and rear smoke boxes, mounted on saddle for easy installation. one set of heat resistant Cast iron fire bars and cast iron doors are part of supply.

- One induced draught fan with motor.

- Two sets of feed water pumps and Motors, pipeline and check valves are provided

- One set of I.B.R quality boiler mountings.

- Automatic water level controller.

- Control panel

We manufacture over a wide standard range Of evaporation capacities ranging from 300 to 6000 Kgs/hr (from and at 100deg c) with standard working pressures of 10.54,15 and17.5 Kgs/cm2.

Horizon Softnet Solutions

Horizon Softnet Solutions