OPERATING PRINCIPLE

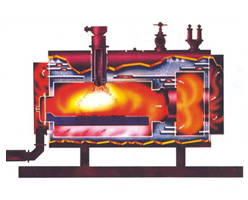

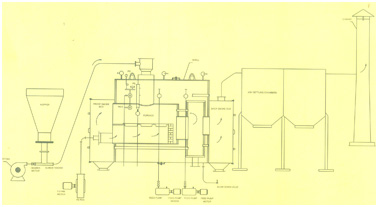

Our Coal/Husk fired packaged boilers are specially designed for burning low/medium grade Coal, Husk which are available in our local markets. The Coal is fed into the hopper after crushing coal in coal crusher for proper sizing. Husk can be fed as such in available condition. From hopper the fuel is fed to a crew conveyor which is driven by a motorized variable speed drive. The speed is regulated according to the steam load on the boiler. From the screw-feeder the fuel is pneumatically transported and fed with a high degree of swirl from the top of the integral furnace. When the fuel particles enter the furnace, they are subjected to intense heating.

As a result, amount 50% of the weight of the fuel burns in suspension and the balance resulting char particles burn on the grate. The air is given from the bottom as well from the top. The primary air is supplied from the bottom of the furnace through specially designed, heat resistant c.i. Fire bars. The secondary air is supplied from the top of the furnace with a high degree of turbulence to the furnace gases and ensure vigorous mixing and complete combustion. The high degree of turbulence enhances combustion efficiency, and ensures high flame temperature and increases radiant heat transfer to the furnace walls. The wedback chamber, at rear of the furnace effectively absorbs the heat from the flame entering the chamber. The flue gases then takes the second and third passes through the smoke tubes, which effectively absorbs all the useful heat resulting in high thermal efficiencies.

HIGH EFFICIENCY

High degree of turbulence caused by the interaction of the primary and secondary air streams enhances heat release rates and ensures high thermal efficiencies of 80+/-2%.

CONSTRUCTION

Our Boilers are manufactured in accordance with the stringent standards laid down by the Indian Boiler Regulation Code. Boiler quality steel plates and tubes are used and strict quality control is enforced at every stage of construction. All welding seams are Xray inspected and hydro-tested.

INSULATION

Our boilers are insulated so that heat losses are minimum thus ensuring high efficiency.

ELECTRICAL

We supply a dust - proof control panel with relays, controls for safe operation and for full overload protection for motors. All motors, wiring and other components conform to the specifications laid down by the Indian Bureau of Standards.

- Boiler with furnace, rear wet back chamber, smoke tubes and fusible plug manufactured, tested and certified by Indian Boiler Regulating authorities.

- Thermal insulation with protective covering.

- One set of specially designed heat-resistant fire-bars with tight sealed fire-door.

- Fuel feeding system comprising of variable speed screw conveyor, transport blower and drop tube in the boiler.

- Feed water system comprising two numbers of motorized feed water pumps, pipe line to boiler and automatic feed water controller.

- IBR Quality boiler mountings comprising of one safety valve, one pressure gauge with syphon, one steam-stop valve, two feed check valves, one blowdown valve and one air-vent valve.

- Forced Draught Fan with primary and secondary air-ducts.

- Control panel for boiler and it's auxillaries.

We manufacture this type of boilers in various capacities from 750 kgs/hr to 4000 kgs/hr with standard pressures of 10.54, 14 and 17 kgs/cm.

Horizon Softnet Solutions

Horizon Softnet Solutions